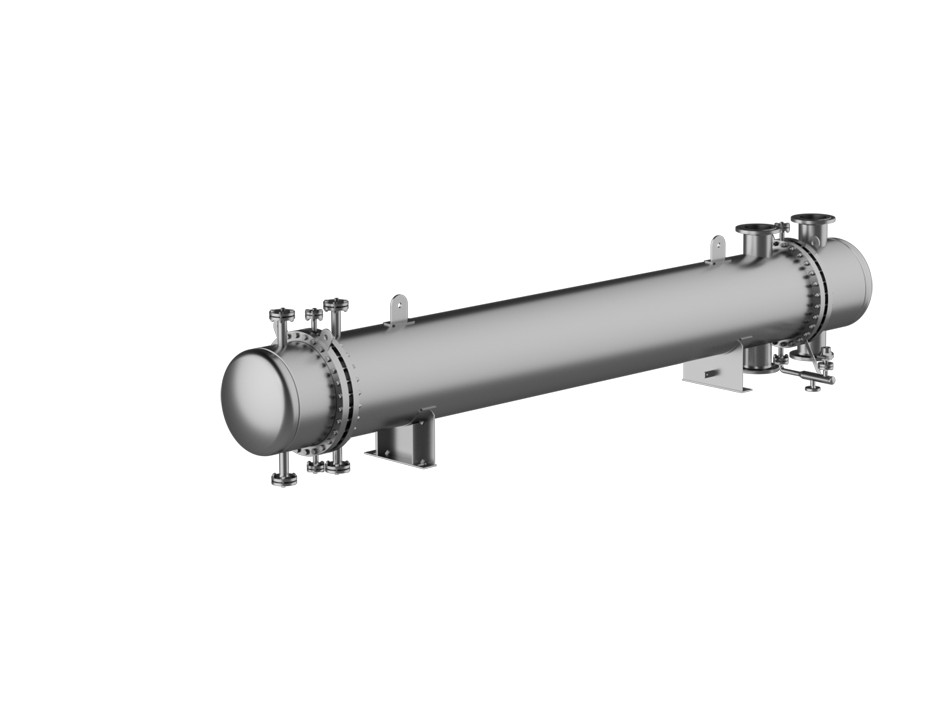

Shell and Tube Heat Exchangers

Efficient heat transfer for a wide range of applications

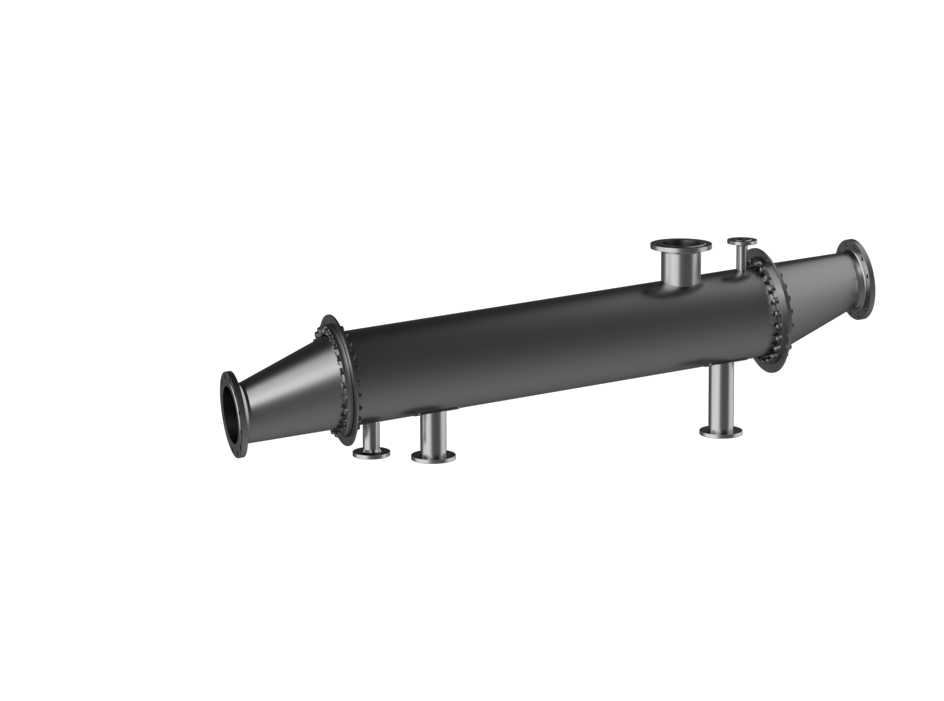

Our shell and tube heat exchangers are designed to transfer heat between fluids with maximum efficiency. Thanks to robust designs, we always guarantee optimal thermal performance.

Definition and Function of Shell and Tube Heat Exchangers

Heat exchangers are devices that serve to transfer heat from one liquid or gaseous fluid through a partition to another fluid. In numerous applications, shell and tube heat exchangers prove to be the most common solution. Thanks to our optimally coordinated designs and materials, we offer not only a wide range of applications but also outstanding thermal performance. This way, you always benefit from a cost-effective and reliable solution.

Due to their usually simple construction, high heat transfer performance, and easy accessibility for inspection, shell and tube heat exchangers are widely used not only in chemical plants. A shell and tube heat exchanger essentially consists of a cylindrical vessel (shell) into which a tube bundle is installed. This bundle consists of parallel tubes welded into round plates with holes, the tube sheets.

Shell and tube heat exchangers have at least two separate spaces: essentially the tube space and the shell space. One fluid flows through the tube bundle (tube space), while the other fluid flows between the tubes in the shell space. Baffles and guide plates in the shell space redirect the fluid and thus improve heat exchange. When using heating steam, it usually flows in the shell space around the tubes, while liquids to be cooled or cooling liquids are passed through the tubes. In special cases, e.g., at very high steam pressures, steam can also be passed through the tubes.

Our Shell and Tube Heat Exchangers

Heating Condensers

Heating condensers, also known as liquefiers, play a crucial role in converting gaseous media into the liquid state.

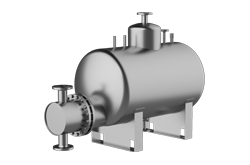

Steam Generators

Steam generators are of great importance, especially in the conversion of liquid media into the gaseous state.

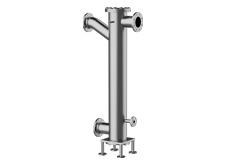

Safety Heat Exchangers

Our safety heat exchangers are equipped with double tubes welded into double tube sheets to create a safety space.

Sterile Heat Exchangers

Our sterile heat exchangers prevent media mixing even in case of leaks in the tube/tube sheet weld connection.

APPLICATION-SPECIFIC

Your markets are our markets. Every year, over a thousand products leave ZILONIS to be deployed worldwide, tackling the most demanding challenges.

/chemie-und-petrochemie.jpg)

/energietechnik.jpeg)

/pharmaindustrie.jpg)

/gebaeudetechnik.jpeg)

/holz-und-papierindustrie.jpeg)